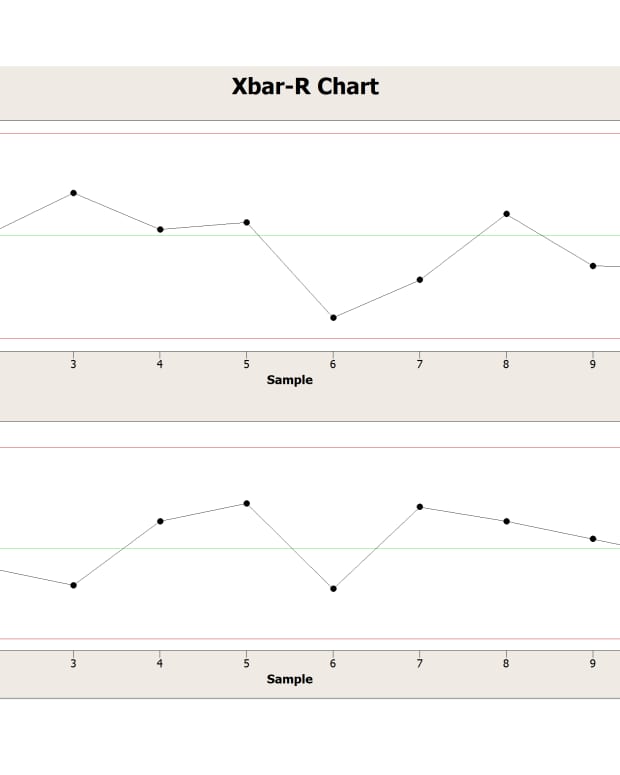

Interpret the results: Examine the generated charts for any points outside the control limits or non-random patterns, which may indicate a lack of process stability or the presence of special cause variation.It will automatically calculate the centerlines and control limits based on the provided data and the appropriate constants from the table. Draw the control charts: Click the "Draw Control Charts" button, and the app will generate the X-bar and R charts using your data.Here's an example of a properly formatted dataset with a subgroup size of 5: 1 97 101 102 98 100 Make sure you separate the columns using tabs. Subgroup Number | Measurement 1 | Measurement 2 |. Data structure: Your data should be organized as follows:.The app will automatically detect the subgroup size based on the number of columns. Your data should be formatted with the first column representing the subgroup number, and the following columns containing the measurements for each subgroup. Input your data: Paste your Excel data into the app's input field.Our X-bar R chart app is designed to make it easy for you to create X-bar R charts from your data. Here's a table of the constants for different subgroup sizes: Subgroup Size (n) To calculate the control limits, you'll need the appropriate constants. where A2, D3, and D4 are control chart constants that depend on the subgroup size (n).

Lower Control Limit (LCL) = CL - (A2 × R-bar).

MINITAB XBAR R CHART HOW TO

This blog post will help you understand the basics of the X-bar R chart, learn the relevant formulas, get familiar with the constants table, and show you how to use our app to create your own X-bar R charts. It is used for continuous data, when individual measurements are collected in subgroups at regular intervals. In the world of statistical process control, the X-bar R chart is a powerful tool used to monitor process stability and variability.

0 kommentar(er)

0 kommentar(er)